5 Ventilation Control

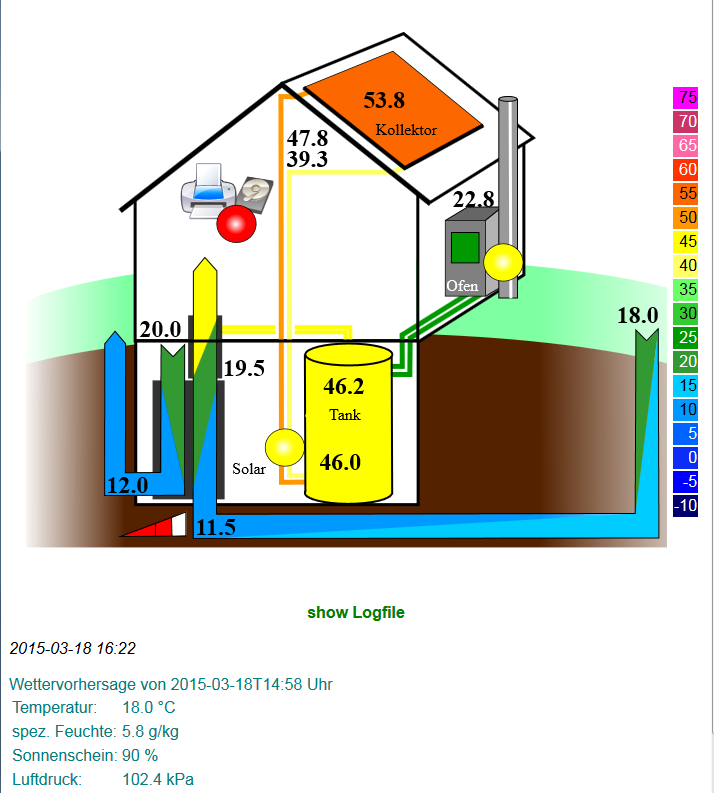

To couple the ventilation (Thermos200, Paul-Lüfutng) to my heating control has two motivations: On first hand I"d like to log and monitor the air temperatures, secondly it might be a good idea to synchronize the periods of maximal ventilation to times the oven is ignited and loading the storage tank.

- approach: Replace the control panel

- approach: Build you power supply and control

1. Replace the control panel

Since the requested Temperatures are provided to the control panel and of course this is used to set the ventilation mode, I thought it should be the easy way to take over this communication - instead of mounting my own temperature sensors and figure out how to operate the blowers.

To do so I connected the RX and TX wire to my RaspberryPi.

While I tried to understand the communication to the control panel, I figured out that the ventilation control and the panel need continuous communication to keep alive. Therefore I wrote a C program to listen to the ventilation and always reply the expected message. If you enable the debug it will depict the messages which are transmitted via the bus.

If this program is started as background task

./thermos200.x&

the ventilation is keept a life.

The Thermos control panel consists only of 5 buttons to operate the system. For each button press one of the standard 133 messages has to exchanged by the button command.

Afterwards the first 138 messages contain the relevant display content to be interpreted.

To exchange these pieces of information between thermos200.c and HV_thermos200.php I use named pipes "FIFO". To get them working without blocking, operating with the necessary rights of program and pipes was a bit of trial and error, but if you follow my example you should be fine.

This way I am able to mimik the control panel, send one button press after the other and display the replied content.

Or to do some data logging I can initiate the sequence to read the temperatures cyclically.

2. Build you power supply and control

By all the experience I got, I"d say, this is the much easier approach.- The ventilators of the Thermos 200 are from ebmpapst type R3GD220-AD11-02. They are directly connected to 230 V; the control PIN may be set either by PWM, or 0 -- 10 V potential (the current at 10 V is of the order of 0.1 mA).

- The DC motor of the bypass is from Bosch type 0132801141, 24 V, 0.3 W. It comes with a build in potentiometer that has a resistance of 5 kOhm, when bypass is open the left resistancy is 3.25 kOhm, the right 1.74 kOhm.

- The build in thermoresistors show values of 13 kOhm at 19 °C.

In other articles I explain, how to control the ventilation by PWM and how to operate the bypass by bridge driver.